-

Capacity for Liquids

Cooling System

211 gal (US)Lube Oil System - Refill

351 gal (US) -

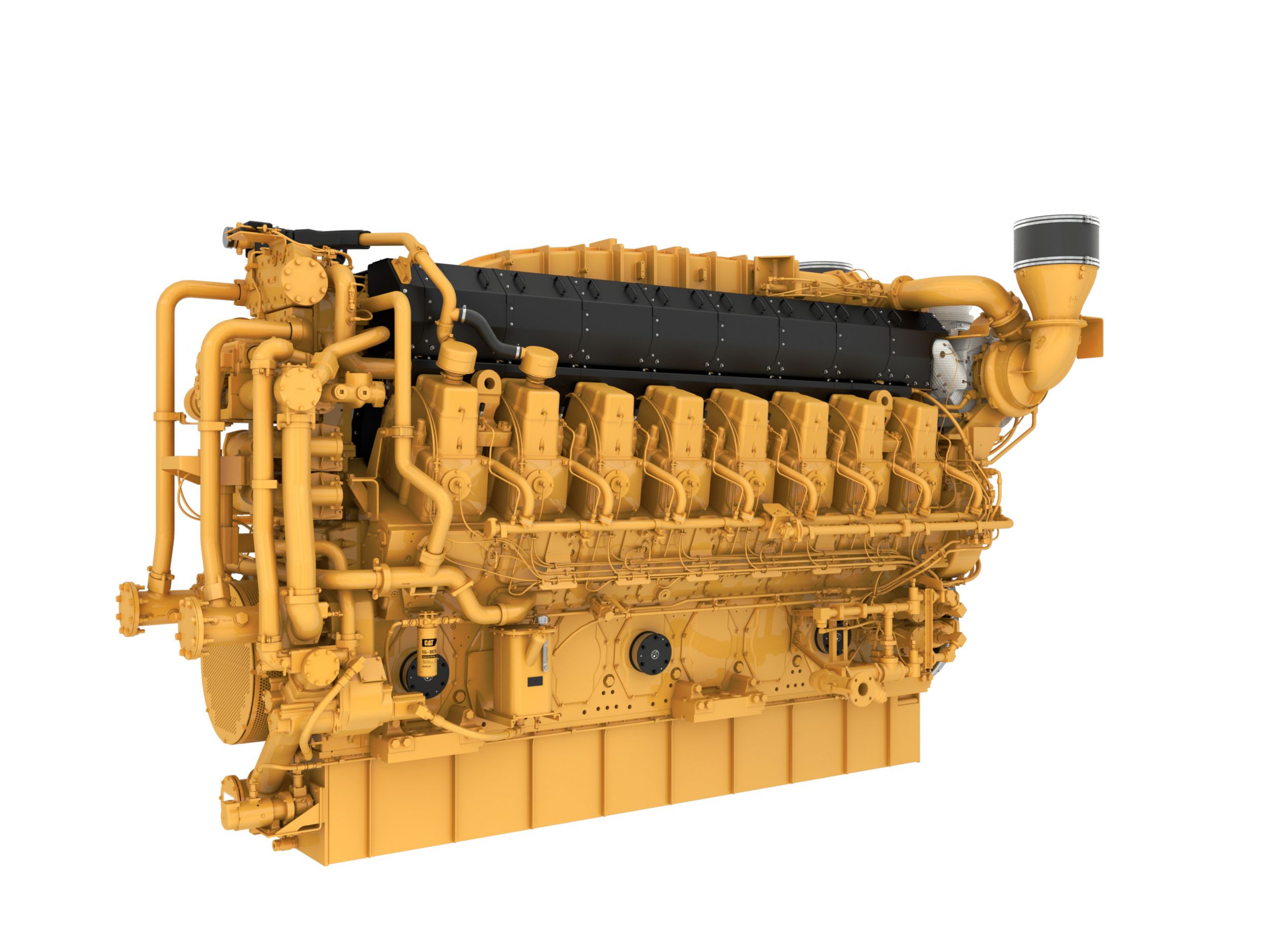

Engine Specifications

Aspiration

Turbocharged-AftercooledBore

11.8 inCompression Ratio

Gen 1 (9.2:1) Gen 2 (7:6:1)Displacement

20698 in³Emissions

NSPS Site Compliant CapableFlywheel Teeth

255Ignition, Protection

Electronic, ADEM™4Maximum Rating

5500 BHPMinimum Rating

5000 BHPOil Change Interval

5000 hoursRotation from Flywheel End

CounterclockwiseStroke

11.8 inWeight - Dry

72000 lb

Air Inlet System

- Air cleaner — standard duty

- Inlet air adapter

Control System

- A4 control system — provides electronic governing integrated with air/fuel ratio control and individual cylinder ignition timing control

Cooling System

- Jacket water pump

- Jacket water thermostats and housing

- Aftercooler pump

- Aftercooler water thermostats and housing

- Single-stage aftercooler

Exhaust System

- Dry wrapped exhaust manifolds

- Vertical outlet adapter

Flywheel & Flywheel Housing

- SAE standard rotation

Fuel System

- Gas supply and and shut-off valves — electronically controlled fuel supply pressure

Ignition System

- A4 control system — senses individual cylinder detonation and controls individual cylinder timing

Instrumentation

- LCD display panel — monitors engine parameters and displays diagnostic codes

Lube System

- Crankcase breathers — top mounted

- Oil cooler

- Oil filter

- Oil pan drain valve

Mounting System

- Engine mounting feet (six total)

Protection System

- Electronic shutoff system with purge cycle

- Crankcase explosion relief valves

- Gas shutoff valve

Starting System

- Air starting system

General

- Paint — Cat yellow

- Vibration dampers

Air Inlet System

- Heavy-duty air cleaner with precleaners

Charging System

- 35 Amp & 65 Amp charging alternators – CSA approved

Exhaust System

- Flexible bellows adapters

- Exhaust expander

- Weld flanges

Fuel System

- Fuel filter

- Gas pressure regulator

- Flexible connection

- Flexible connection

Instrumentation

- Remote data monitoring and speed control

- Compatible with Cat Electronic Technician (ET) and Data View

- LCD display panel

- Color HMI display

- Modbus and Ethernet capable

Lube System

- Air or electric motor-driven prelube

- Duplex oil filter

Mounting System

- Mounting plates (set of six)

Power Take-Offs

- Front stub shafts

Starting System

- Air pressure reducing valve

- Natural gas starting system

General

- Engine barring device

- Damper guard