-

Capacity for Liquids

Cooling System

14.5 gal (US)Lube Oil System - Refill

39 gal (US) -

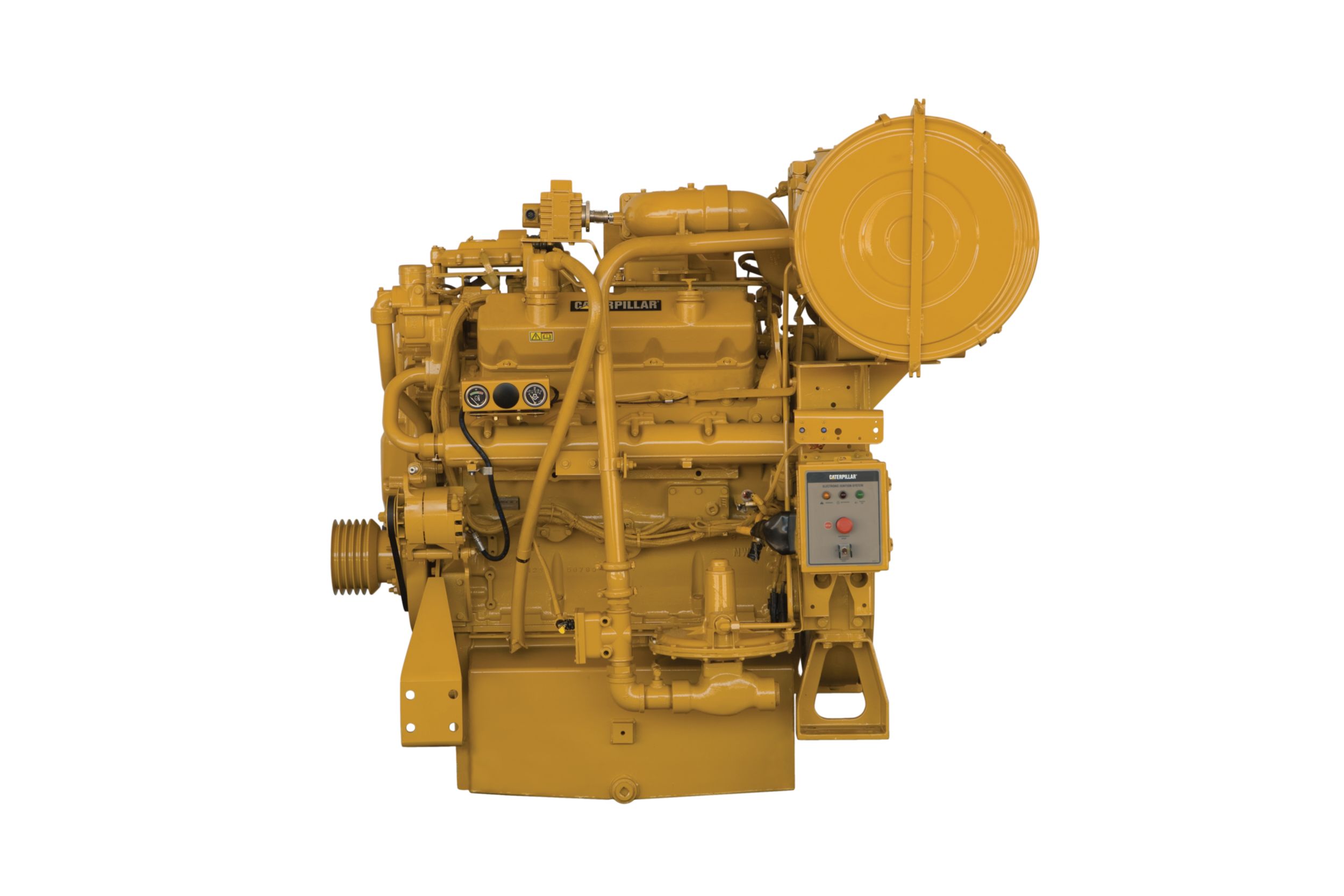

Engine Specifications

Aspiration

Turbocharged-AftercooledBore

5.4 inCompression Ratio

8.5:1Displacement

1099 in³Emissions

NSPS Site Compliant Capable or Non-regulatedFlywheel Teeth

136Flywheel and Flywheel Housing

SAE No. 0Ignition, Protection

Cat EISMaximum Rating

425 BHPMinimum Rating

425 BHPOil Change Interval

750 hoursRotation from Flywheel End

CounterclockwiseStroke

6 inWeight - Dry

4950 lb

Air Inlet System

- Air cleaner — single element with service indicator

Control System

- Electronic governor

- Air/fuel ratio control

Cooling System

- Thermostats and housing

- Jacket water pump

- Aftercooler water pump

- Aftercooler core

Exhaust System

- Watercooled exhaust manifolds

- Dry exhaust elbow

Flywheel & Flywheel Housing

- SAE No. 0 flywheel

- SAE No. 0 flywheel housing

- SAE standard rotation

Fuel System

- Gas pressure regulator (1.5 to 5 psi gas supply required)

- Natural gas carburetor

Ignition System

- Cat Electronic Ignition System (EIS) with detonation sensitive timing

Instrumentation

- Service meter

Lube System

- Crankcase breather — top mounted

- Oil cooler

- Oil filter — RH

- Oil pan — deep sump

- Oil filler — RH in valve cover and RH dipstick

Mounting System

- Engine supports

Protection System

- Detonation sensitive timing control

- Shutoff

General

- Paint — Cat yellow

- Crankshaft vibration damper and pulleys

- Lifting eyes

- Cylinder block inspection covers

Air Inlet System

- Air cleaner — two-stage

- Air inlet adapter

- Precleaner

- Air cleaner rain cap

Charging System

- Battery chargers

- Charging alternators

- Ammeter gauge

- Ammeter gauge and wiring

- Control mounting

Cooling System

- Radiators

- Blower fan and fan drives for customer suppliedradiators

- Expansion tank

- Heat exchangers

Exhaust System

- Flexible fittings

- Elbows

- Flanges

- Rain caps

- Mufflers

- Exhaust manifold — instrument holes at each port

Fuel System

- Dual gas regulator

- Carburetor kits

- Fuel filter

Ignition System

- CSA ignition

- Ignition ground wiring harness

- Power supply

Instrumentation

- Alarm module

- Gauges and instrument panels

Mounting System

- Vibration isolators

Power Take-offs

- Auxiliary drive pulleys

- Enclosed clutch and clutch support

- Front stub shaft

- Flywheel stub shaft

- Pulley removal

Protection System

- Gas valves

- Status control box interconnect wiring harness

Starting System

- Air starting motor

- Air pressure regulator

- Air silencer

- Electric start control

- Electric starting motors — single 24V

- Starting aids

- Battery sets — (24V dry), cables, and rack

General

- Special paint