-

Capacity for Liquids

Cooling System

5.25 gal (US)Lube Oil System - Refill

11.9 gal (US) -

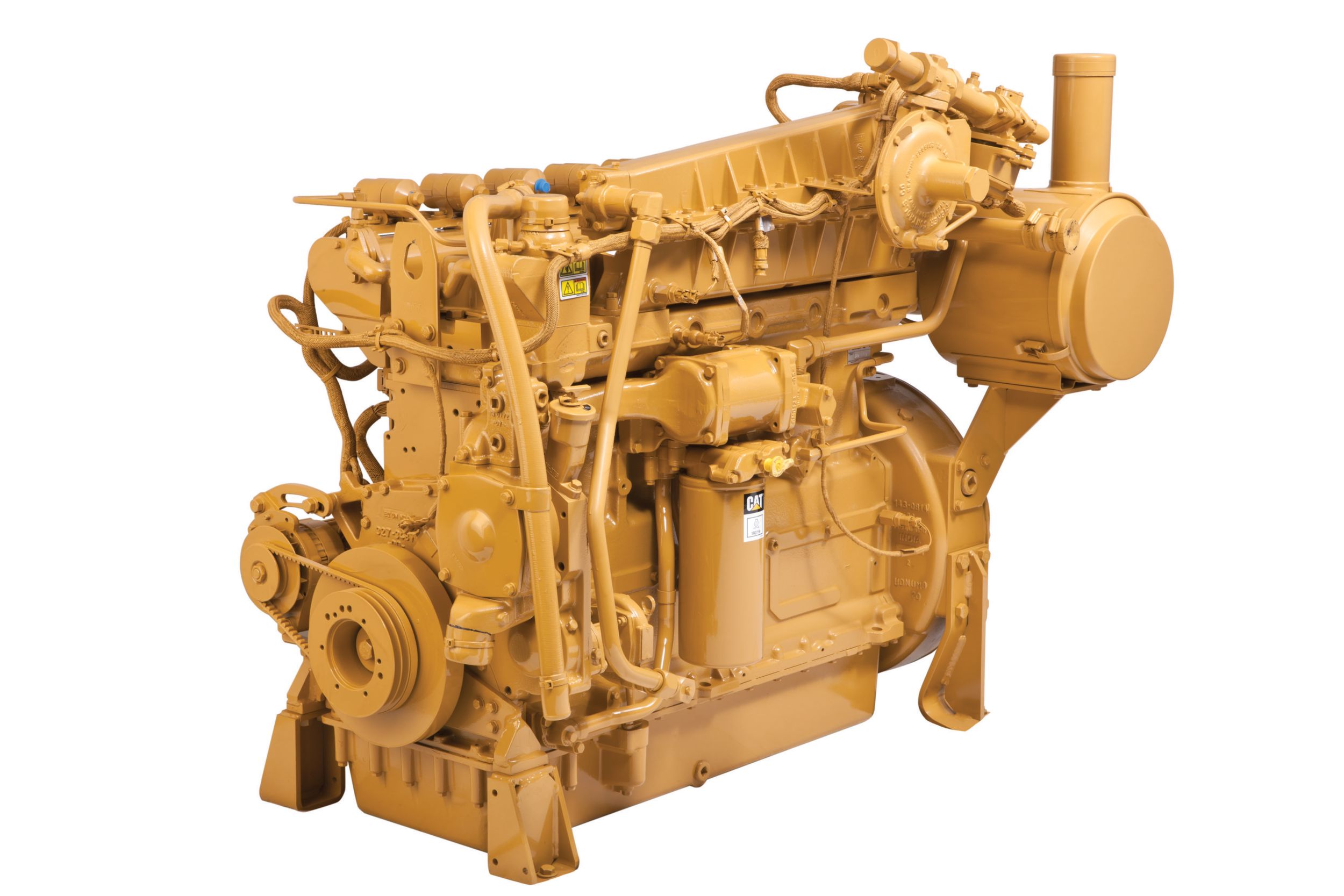

Engine Specifications

Air/Fuel Ratio Control

ADEM A4Aspiration

Naturally Aspirated or Turbocharged-AftercooledBore

4.8 inCompression Ratio

10.5:1Displacement

638 in³Emissions

NSPS 2010Flywheel Teeth

156Flywheel and Flywheel Housing

SAE No. 1Ignition, Protection

ADEM A4Maximum Rating

211 BHPMinimum Rating

145 BHPOil Change Interval

750 hoursRotation from Flywheel End

CounterclockwiseStroke

6 inWeight - Dry

2450 lb

Air Inlet System

- Air cleaner — intermediate duty, dry

- Air cleaner rain cap (shipped loose)

- Service indicator

Control System

- ADEM A4

Cooling System

- Thermostats and housing — full open temperature 97°C (207°F)

- Jacket water pump — gear-driven, centrifugal, non-self-priming

Exhaust System

- Exhaust manifolds — watercooled

- Exhaust elbow — dry

- 102 mm (4 in)

- Three-way catalyst — 1.0 g NOx and 0.5 g NOx catalyst options

Flywheels & Flywheel Housings

- Flywheel, SAE No. 1

- Flywheel housing, SAE No. 1

- SAE standard rotation

Fuel System

- Air/fuel ratio control

- Gas pressure regulator

- Requires 10.3-34.5 kPa (1.5-5 psi) gas

- Natural gas carburetor

Ignition System

- ADEM A4 ignition

Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filter

- Oil pan, full sump

- Oil filler and dipstick

Protection System

- The following parameters include alarm and shutdown

Charging Alternator

- 24V, 35A alternator

- 24V, 35A CSA alternator*

Cooling System

- Radiators

- Jacket water pump inlet adapter

Exhaust System

- Exhaust flex fitting — ANSI flange

- Exhaust elbow

- Exhaust flange — ANSI flange

Guards

- Fan guard

- Damper guard

Ignition System

- CSA certified electronics and ignition

Instrumentation

- Operator interface panel

- Operator interface panel enclosure

- 15', 20' and 50' interconnect harness

Starting System

- Air pressure regulator

- Air start silencer

- Vane starter

- Electric starter

- Turbine starter