New CAT Equipment

D8 Dozer

Get a Quote

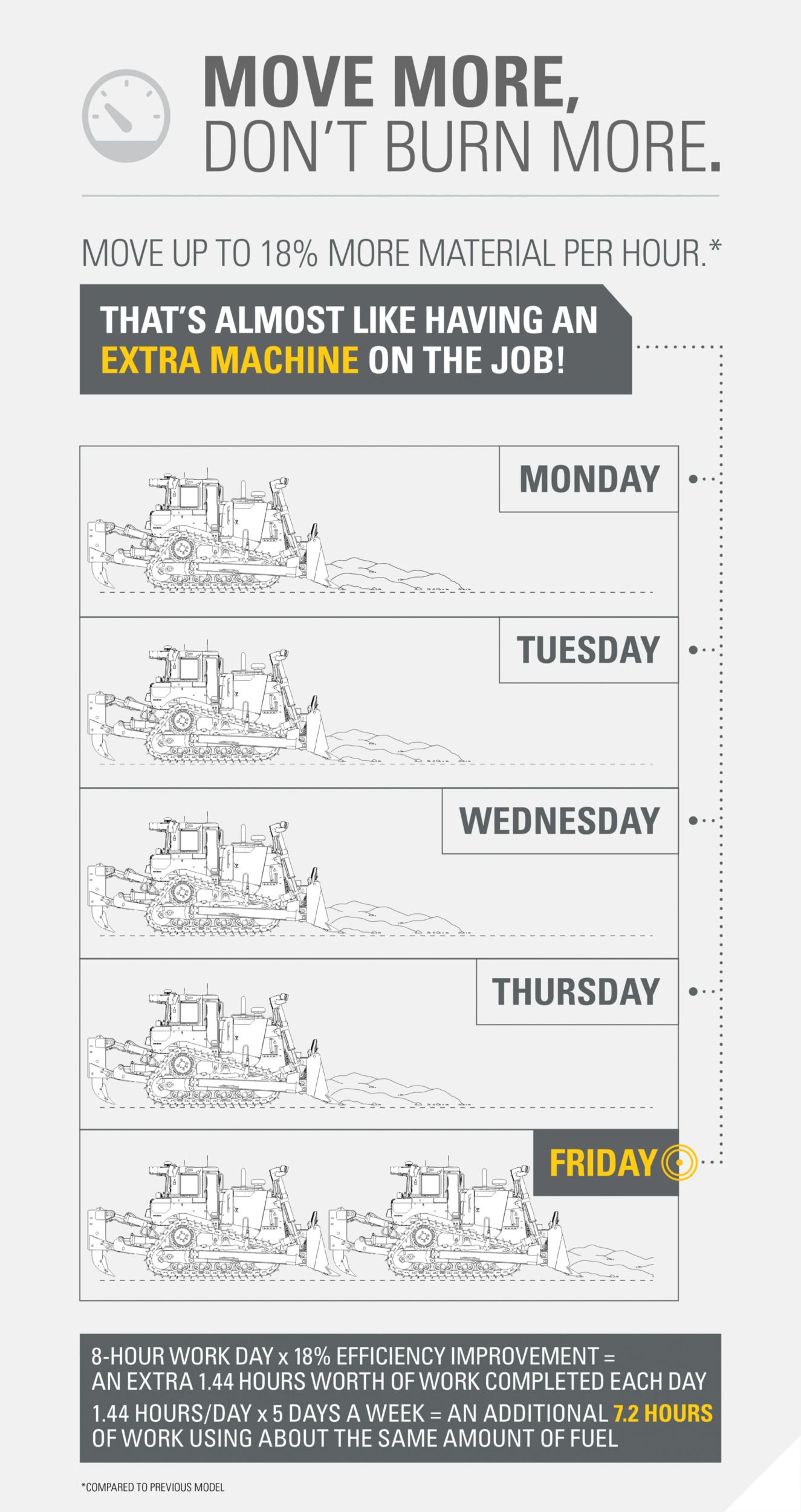

Zero Additional Fuel

Move more material without burning more fuel in most applications. Use up to 11% less fuel in lighter applications.

Up To 18% More material per hour

Fully automatic transmission, added power and steering performance team up for a new level of productivity. Larger blade capacity gets the job done in fewer passes.

Move More, Spend Less

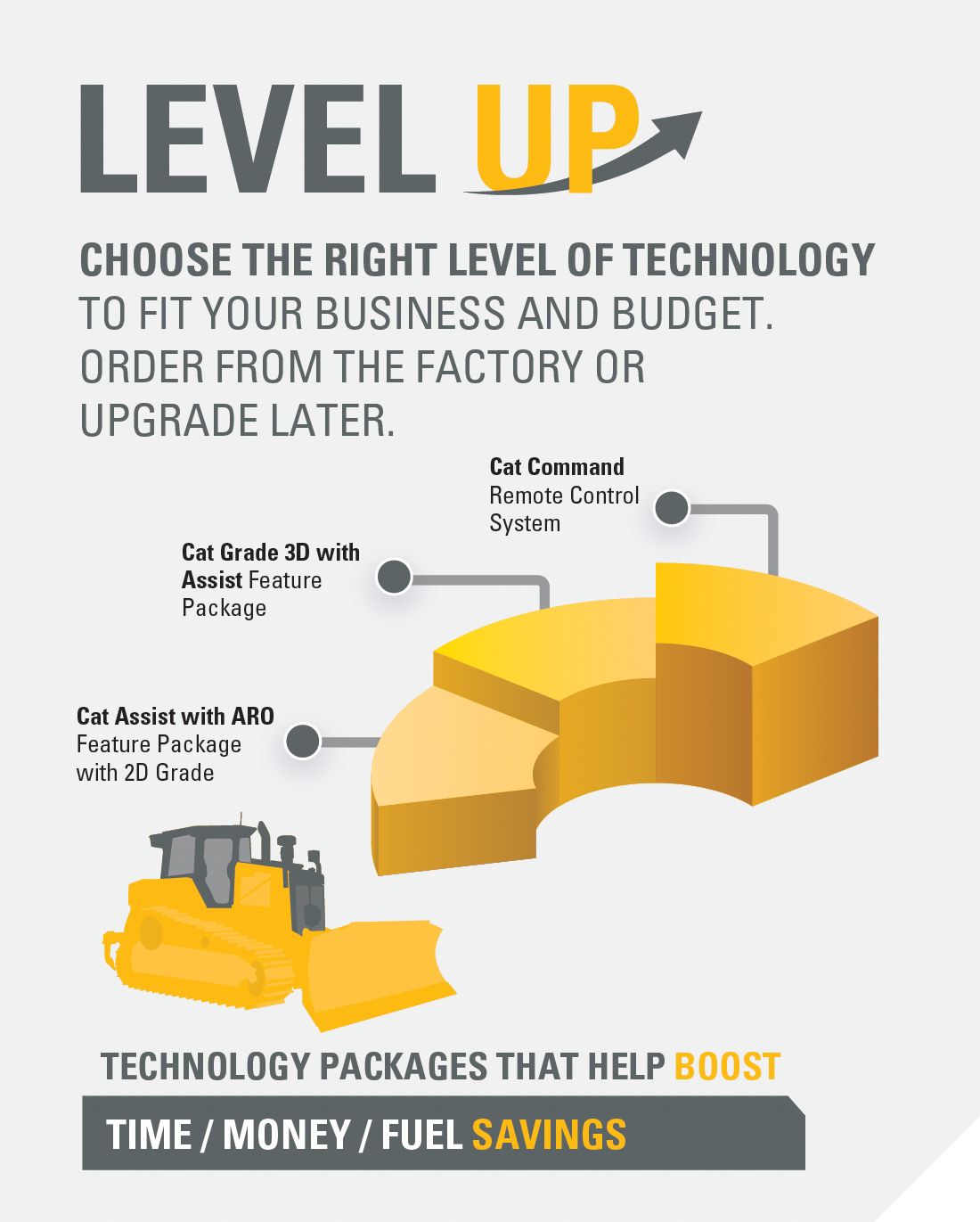

Grade technologies help you work more precisely for faster results, less rework. Blade and undercarriage options help you take on the harshest conditions at a lower overall cost.

Learn more about the D8 Dozer

-

Air Conditioning System

Air Conditioning

The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 2.5 kg of refrigerant which has a CO2 equivalent of 3.575 metric tonnes. -

Engine

Emissions

U.S. EPA Tier 4 Final/EU Stage V/Korea Stage VEngine Model

Cat C15Net Power - ISO 9249 (DIN)

359 mhpNet Power - ISO 9249/SAE J1349

354 HPNote (1)

Net power at 1,900 rpm. Net power advertised is the power available at the engine flywheel when the engine is equipped with a fan, air cleaner, clean emissions module and alternator. Advertised power is tested per the specified standard in effect at the time of manufacture.Note (2)

Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels up to: 20% biodiesel FAME (fatty acid methyl ester) ** or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details. ** Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).Note (3)

Machine Build Number 21BPower - Net

354 HP -

LGP

Blade

Semi-Universal (SU)Blade Capacity

12.9 yd³Ground Pressure

8 psiOperating Weight

84906 lbWidth of Standard Shoe

38 in -

LGP Waste Handler

Blade

Semi-Universal (SU) LandfillBlade Capacity

27.9 yd³Ground Pressure

8.8 psiOperating Weight

93672 lbWidth of Standard Shoe

38 in -

Service Refill Capacities

DEF Tank

6 gal (US)Fuel Tank

165 gal (US) -

Standard SU

Blade

Semi-Universal (SU)Blade Capacity

13 yd³Ground Pressure

13 psiOperating Weight

88698 lbWidth of Standard Shoe

24 in -

Sustainability

Recyclability

98% -

Transmission

Power Train

Fully Automatic 4-Speed Powershift -

Waste Handler

Blade

Semi-Universal (SU) LandfillBlade Capacity

21 yd³Ground Pressure

13 psiOperating Weight

88206 lbWidth of Standard Shoe

24 in -

Weights

Operating Weight

87600 lb

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

Power Train

- C15 Diesel Engine, Electronic Unit Injection (EUI), Aftertreatment to meet U.S. EPA Tier 4 Final/Korea Stage V emission standards

- 24V electric start

- Air-to-air aftercooler (ATAAC)

- Air filter with electronic service indicator

- Extended life coolant

- Auto reversing suction fan

- Four planet, double-reduction planetary final drives

- Electric fuel priming pump

- High performance single plane cooling system

- Electronic parking brake

- Precleaner, strata-tube dust ejector

- Prescreener

- Shift management: Full Auto Shift

- Sound attenuated exhaust system

- Automatic ether starting aid

- Torque divider with lock-up clutch

- Transmission control module, electronic

- Transmission, electronically-controlled powershift

- Turbocharger

- Water separator

Operator Environment

- Access/egress lighting with shutdown timer

- Adjustable armrests

- Air suspension seat

- Cab, ROPS/FOPS, sound suppressed

- Decelerator pedal

- Heater and ventilation

- Interior LED courtesy lights

- Rearview mirror

- Provision for wire passage in/out of cab

- Radio, AM/FM, Bluetooth

- ROPS mounted air conditioner

- Seat belt, retractable

- Steering control, direction and speed control thumb switches with recall button

- Touch screen operator interface: Electronic monitoring system, Diagnostic service information, Operator preferences

- Wipers, intermittent

Cat Technology

- Grade control ready

- Compatibility with radios and base stations from Trimble, Topcon, and Leica

- Capability to install 3D grade systems from Trimble, Topcon, and Leica

Power Train, Engine, Brakes

- Brakes, Basic or Extreme Service

- Engine precleaner, basic or with screen

Bottom Guards

- Standard

Electrical

- Back-up alarm

- Converter, 24V to 12V

- Diagnostic connector

- Ground level service center with hour meter

- Horn, forward warning

Final Drives

- Final drives: LGP or Guarded

- Final drives: Standard, Guarded or Arctic

Hydraulics

- Dozer tilt and fan hydraulics: Single Tilt or Dual Tilt

- Electronically enabled quick drop valve

- Hydraulics, electronically controlled, load-sensing dozer lift and tilt

- Hydraulics, electronically controlled, load-sensing rear hydraulics, ripper or winch ready

- Hydraulics, independent steering and work tool pumps

Other Standard Equipment

- Engine compartment service light

- Equalizer bar, pinned

- Front pull device

- Hinged bottom guards

- HVAC box, corrosive resistant

- Product Link

- S-O-S sampling ports

- 6-light package

- Electronically controlled power differential steering

- Vandalism protection for fluid compartments

Starters, Batteries, And Alternators

- Alternators: 150 Amp, Basic or Ducted

- Batteries: Heavy duty or Arctic

- Engine coolant heater (120V)

- Starting receptacle, auxiliary

Undercarriage

- Positive Pin Retention Track (44 Section, sealed and lubricated, single grouser shoes)

- 610 mm (24 in) Extreme Service track

- 8-roller tubular track roller frame (Carrier roller ready)

- Gauge arrangements: Standard or LGP

- Rollers and idlers, lifetime lubricated

- Sprocket rim segments, replaceable

- Suspension-type undercarriage

- Track adjusters, hydraulic

- Track guide

- Two-piece master links

NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

Power Train, Engine, Brakes

- C15 Diesel Engine, Electronic Unit Injection (EUI), Aftertreatment to meet EU Stage V emission standards

- Engine, thermal shield

- Oil change system, high speed

- Radiator, 6.35 fins per inch, debris

Operator Environment

- Cab glass: Single pane, Enhanced Dual Pane or 40 psi

- Cab platform: Standard, Quick Opening or 5th Percentile

- Cab seat: Cloth, heated

- Cab seat: Heated and ventilated

- Visibility arrangements: Basic or Single camera

Cat Technology

- Attachment Ready Option (ARO), single tilt or dual tilt

- AutoCarry/AutoRip, single tilt or dual tilt

- Cat Grade with 3D

- Command for Dozing Ready

- Machine control, basic, single tilt or dual tilt

- Product Link: Cellular or Dual mode

Bulldozers

- 8A

- 8SU LGP

- 8SU/U: basic, guarded or dual tilt guarded

- 8U LGP: single tilt guarded or dual tilt guarded

Blades

- Angle Blade

- LGP Angle

- LGP SU

- LGP SU Landfill

- Semi-Universal (SU)

- SU Landfill with Wear Plate

- SU with Performance Cutting Edges

- SU with Push Plate

- SU with Rock Guard, Performance Cutting Edges

- SU with Rock Guard, Wear Plate

- Universal

- Universal Landfill

- Universal with Rock Guard, Wear Plate

- FirstCut cutting edges (SU blades)

Undercarriage

- Positive Pin Retention (PPR) Undercarriage: Suspended, Guarded or Arctic

- 610 mm (24 in) Moderate Service PPR Track

- 610 mm (24 in) Super Extreme Service PPR Track

- 610 mm (24 in) Extreme Service PPR Track, trapezoidal

- 660 mm (26 in) Moderate Service PPR Track

- 660 mm (26 in) Extreme Service PPR Track

- 660 mm (24 in) Extreme Service PPR Track, trapezoidal

- 660 mm (24 in) Super Extreme Service PPR Track, trapezoidal

- 711 mm (28 in) Moderate Service PPR Track

- 711 mm (28 in) Extreme Service PPR Track

- 711 mm (28 in) Moderate Service PPR Track, trapezoidal

- 711 mm (28 in) Extreme Service PPR Track, trapezoidal

- 965 mm (38 in) Moderate Service PPR Track

- 965 mm (38 in) Extreme Service PPR Track

- 965 mm (38 in) Extreme Service PPR Track, trapezoidal

- Heavy duty, extended life undercarriage track (44 Section, sealed and lubricated, single grouser shoes)

- Heavy duty, extended life undercarriage: Suspended, Guarded or Arctic

- 610 mm (24 in) Moderate Service HDXL Track

- 610 mm (24 in) Extreme Service HDXL Track

- 610 mm (24 in) Super Extreme Service HDXL Track

- 660 mm (26 in) Extreme Service HDXL Track

- 660 mm (26 in) Extreme Service HDXL Track, trapezoidal

- 711 mm (28 in) Extreme Service HDXL Track

- 965 mm (38 in) Extreme Service HDXL Track

- 965 mm (38 in) Extreme Service HDXL Track, trapezoidal

- Carrier rollers: Suspended, Suspended Arctic or No carrier rollers

Bottom Guards

- Bottom guards with front counterweight

- Heavy duty, sealed

- Powered

- Wood chip

Electrical

- Light, warning strobe

- Lighting groups: Basic, Premium or Sweeps

- Mount, light, warning strobe

Guards

- Fan debris guard

- Fast fuel guard

- Fuel tank guard

- Grill debris guard

- Rear screen

- Front striker bars

- Sweeps group

Hydraulics

- Rear attachment hydraulics: Ripper, Winch or None

Other Attachments

- Black paint, blade

- Additional counterweight

- Ecology drains

- Grab handles, push arm

- PA140VS winch

- W12 E PTO winch

- Window shades

Rear Attachments

- Rear counterweight

- Rigid drawbar

- Multi-shank ripper

- Multi-shank ripper with striker bar

- No rear attachment

- PA140VS winch, variable speed

- Rear striker bar

- Single shank ripper with pin puller

- Single shank ripper with puller and striker bar

- Single shank ripper with striker bar

Ripper Shank Teeth

- Multi-shank

- Single shank

- Single shank, deep ripping