-

Dimensions & Weights

Maximum Dry Weight

4299 lbMaximum Height

51.2 inMaximum Length

76 inMaximum Width

47.4 inMinimum Dry Weight

4000 lbMinimum Height

47.2 inMinimum Length

73 inMinimum Width

44.6 in -

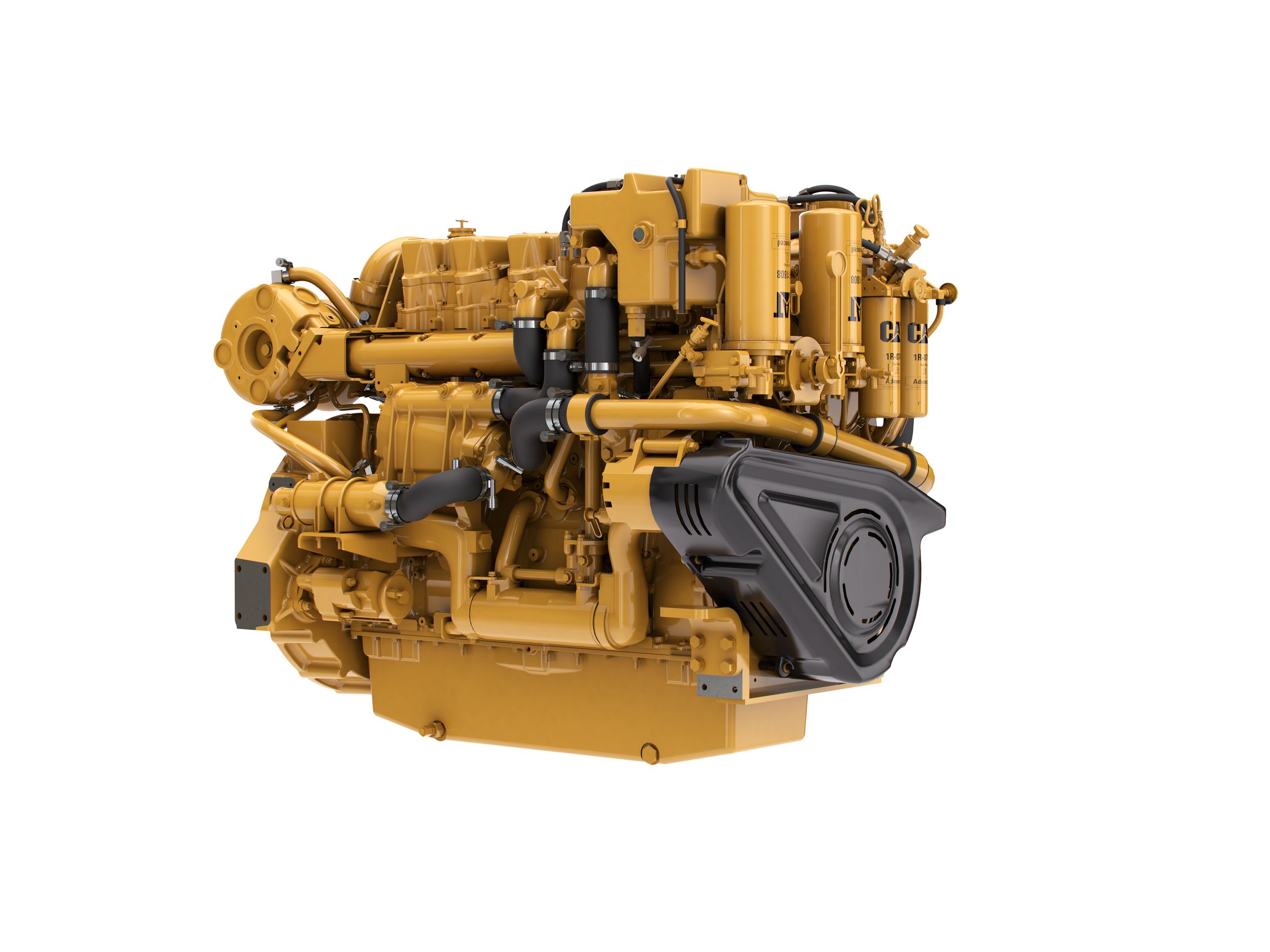

Engine

Aspiration

TA,TTABore

5.7 inConfiguration

In-line 6, 4-Stroke-Cycle DieselDisplacement

1106 in³Emissions

EPA Tier 3, IMO II, EU Stage IIIARotation from Flywheel End

CounterclockwiseSpeed Range

2100-2300 rpmStroke

7.2 in -

Ratings

Power Range

814-1015 mhp, 803-1001 bhp, 599-747 bkW

AIR INLET SYSTEM

- Separate circuit after-cooled (SCAC)

- Open Crankcase Ventilation (OCV) system

- Turbocharger, jacket water cooled

- Turbocharger inlet, 152 mm (6 in) OD straight connection

COOLING SYSTEM

- Separate Circuit After-Cooling (SCAC) for both HEX and Keel cooled engines

- Engine JW and SCAC Shell & Tube Heat Exchangers for HEX cooled engines

- SCAC pump, gear driven, for HEX cooled engines only

- Jacket water pump, gear driven

- Sea water pump, bronze impeller, gear driven

- SCAC and JW shunt tanks for maintaining proper pump inlet pressures

EXHAUST SYSTEM

- Water-cooled exhaust manifold & turbocharger

- 152 mm (6 in) round flanged outlet

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel Housing, SAE No. 0

- Flywheel, 18 inch, 136 teeth

- SAE standard rotation

- SAE No. 1, Flywheel: 14 inch, 113 teeth

FUEL SYSTEM

- Front service simplex fuel system

- Fuel transfer pump, gear driven

- Manual fuel priming pump

- Hybrid fuel line design

LUBE SYSTEM

- Front service simplex oil system

- Center sump oil pan:

- Front and top service oil filler locations

- Front service dipstick

- Oil pump, gear driven

POWER TAKE-OFFS

- Poly-V groove for alternator drive

- NOTE: There are no standard power take-offs available

GENERAL

- Front damper guard

- Front service engine

- Common electrical bonding point

- Engine does not ship with zinc components

- Engine is certified to D2/E2 emissions cycles

- CERTIFIED TO 2013 EPA TIER 3 AND IMO II MARINE COMMERCIAL PROPULSION (E3 CYCLE) EMISSION STANDARDS

- CERTIFIED TO EU STAGE IIIA AND CCNR STAGE II (E3 CYCLE) EMISSIONS STANDARDS.

- NOTE: Ratings listed below can also be used in Recreational / Pleasure Craft applications.

CONTROL SYSTEM

- Programmable low idle

- WOSR (Wide Operating Speed Range) available for EPA Tier 3 - B and C Ratings

- Adjustable High Idle (TEL) - EPA Tier 3 WOSR Ratings Only

- Electronic diagnostics and fault logging

- Engine and transmission monitoring (speed, temperature, pressure)

- Electronic fuel/air ratio contro

- Engine Protection Mode for extended ambient conditions - EPA Tier 3 Ratings Only

- Torque Limiting functionality for WOSR ratings only

- 70-pin customer connector

- Three types of throttle inputs (primary/ secondary PWM, 0-5V, 4-20mA +/-

EXHAUST SYSTEM

- Dry Elbows

- Water-Cooled Elbows

- Flexible Fitting

- Flange

- Muffler

- Muffler Spark Arresting

CHARGING SYSTEM

- Battery Chargers

- Charging Alternators

- Alternator Mounting Group

- Ammeter

CONTROL SYSTEM

- MECP I

- CATERPILLAR ALARM AND PROTECTION

COOLING SYSTEM

- AUX EXPANSION TANK FLANGE KIT

FUEL SYSTEM

- Duplex Fuel Filters

- Flexible Fuel Lines

- Fuel Cooler

- Primary Fuel Filters

INSTRUMENTATION

- Instrument Panels

- OEM Wiring Harness

- Engine to Engine Harness

- Gauges

- Transmission Sensors

- Oil Level Sensor

LUBE SYSTEM

- Duplex Oil Filters

- Transmission Oil Cooler

- Sump Pump

MOUNTING SYSTEM

- Vibration Isolators

- Front Support

- Rear Support

POWER TAKE-OFFS

- NOTE: PTO OPTIONS REQUIRE TORSIONAL VIBRATION ANALYSIS

- Crankshaft Pulleys

- Front Stub Shaft

- Hydraulic Pump Drive Adapter

- Front Enclosed Clutch

PROTECTION SYSTEM

- Marine Classification Society and SOLAS

- Marine Classification Society and Fire Resistance

STARTING SYSTEM

- STARTING SYSTEM Electric Starting Motors - Single 24 Volt

- Air Starting Motor

- Air Start Accessories

- Starting Aids - JW Heaters

- Battery Sets - 24 Volt - Dry