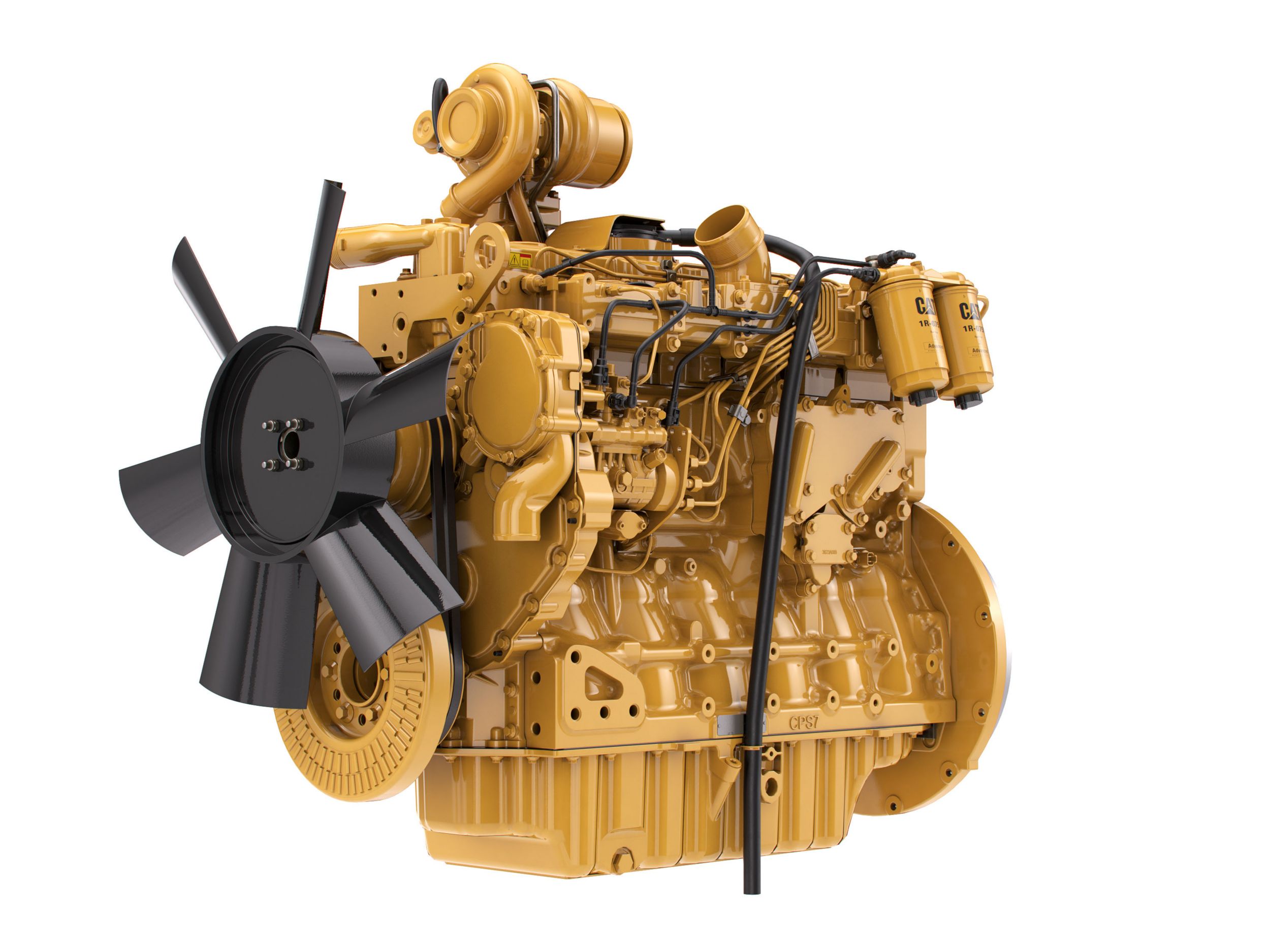

Demanding conditions, applications and environments make Cat® C7.1 Industrial Diesel Engines in this power range the perfect solution for your severe duty equipment. With decades of diesel engine innovation and expertise behind these engines, they deliver the low operating costs and legendary Cat reliability and durability that give you a powerful advantage. More importantly, they're backed by the world-class Cat dealer network ready to service and support every Cat industrial engine. Industries and applications powered by C7.1 engines include: Agriculture, Ag Tractors, Aircraft Ground Support, Bore/Drill Rigs, Chippers/Grinders, Combines/Harvesters, Compactors/Rollers, Compressors, Construction, Cranes, Crushers, Feller Bunchers, Forestry, Forklifts, General Industrial, Hydraulic Power Units, Irrigation Equipment, Loaders/Forwarders, Material Handling, Mining, Mobile Earthmoving Equipment, Mobile Sweepers, Paving Equipment, Pumps, Skidders, Specialty Ag Equipment, Sprayers, Trenchers and Underground Mining Equipment. C7.1 engines, with ratings: 105-162 bkW (140-220 lb) @ 1950-2200 rpm, meet China Stage II, U.S. EPA Tier 2 equivalent, EU Stage II equivalent emission standards. They are available in China and non-regulated areas.