New CAT Equipment

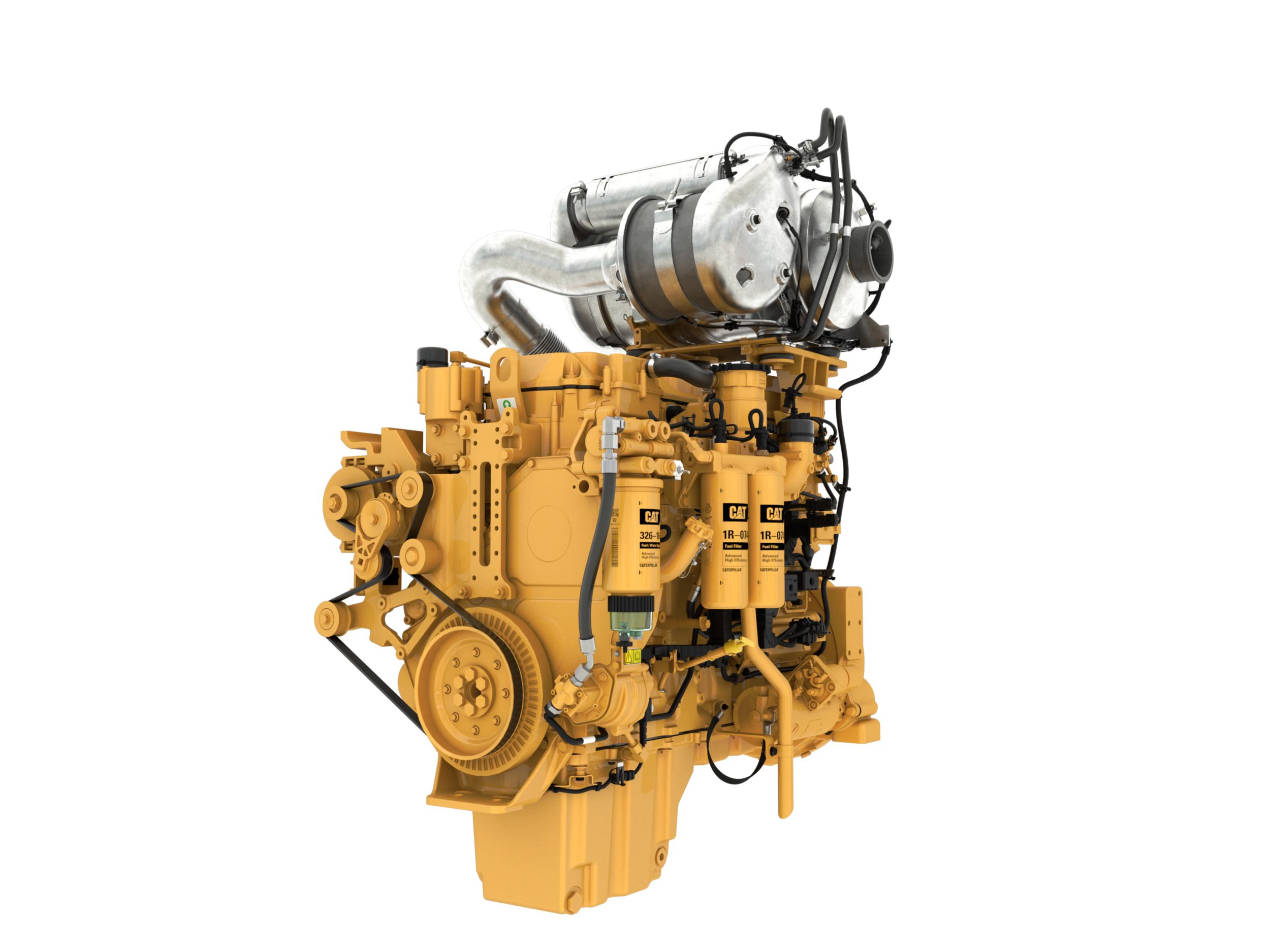

Cat® C13B Diesel Engine

Get a Quote

Peak Power Increased Up To 20% Compared to Previous Models

Over 120 MILLION hours of customer application experience

Engine package is 32% lighter, compared to previous models

Learn more about the Cat® C13B Diesel Engine

-

Aftertreatment Dimensions

Height

18.1 inLength

35.3 inWeight

220 lbWidth

31.8 in -

Emission Standards

Emissions

EU Stage V, U.S. EPA Tier 4 Final, Korea Stage V, Japan 2014, China NRIV -

Engine Dimensions - Approximate

Height

45 inLength

50 inWeight - Net Dry - Basic Operating Engine Without Optional Attachments

2480 lbWidth

39 in -

General

Aftertreatment

DOC+DPF+SCRAspiration

Turbocharged-Aftercooled (TA)Bore

5.1 inCombustion System

Direct InjectionCompression Ratio

15.8:1Displacement

762.8 in³Engine Configuration

In-Line 6Rotation from Flywheel End

CounterclockwiseStroke

6.2 in -

Power Rating

Maximum Power

577 HPMaximum Torque

1943 lb-ft @ 1400 rpmMinimum Power

456 HPRated Speed

1800-2100 rpm

Air Inlet System

- Turbocharged

- Air-to-Air Aftercooled

- Front or rear exhaust configurations available

Control System

- Electronic control system

- Over-foam wiring harness

- Automatic altitude compensation

- Power compensated for fuel temperature

- Configurable software features

- Engine monitoring system SAE J1939 broadcast and control

- Integrated Electronic Control Unit (ECU)

- Remote fan control

Cooling System

- Vertical or RH thermostat outlet

- Centrifugal water pump

- Guidance on cooling system design available through your dealer to ensure equipment reliability

Flywheels and Flywheel Housing

- Available SAE No. 1 power take-off with optional SAE B or SAE C power take-off drives. Engine power can also be taken from the front of the engine with optional attachments.

Fuel System

- Mechanical Electronic Unit Injector fuel system (MEUI-C)

- Primary fuel filter

- Secondary and tertiary fuel filters

- Fuel transfer pump

- Electronic fuel priming

Lube System

- Open crankcase ventilation system

- Oil cooler

- Oil filler

- Lube oil filter

- Oil dipstick

- Gear driven oil pump

- Choice of front, rear or center sumps

- Open crankcase ventilation system with fumes disposal (OCV filter system required for EU Stage V certification engines)

Power Take Off (PTO)

- SAE B or SAE C power take off (PTO) drives. Engine power can also be taken from the front of the engine on some applications.

General

- Caterpillar yellow paint, with optional colors available at request

- Vibration damper

- Lifiting eyes