-

Emission Standards

Emissions

Non-Certified -

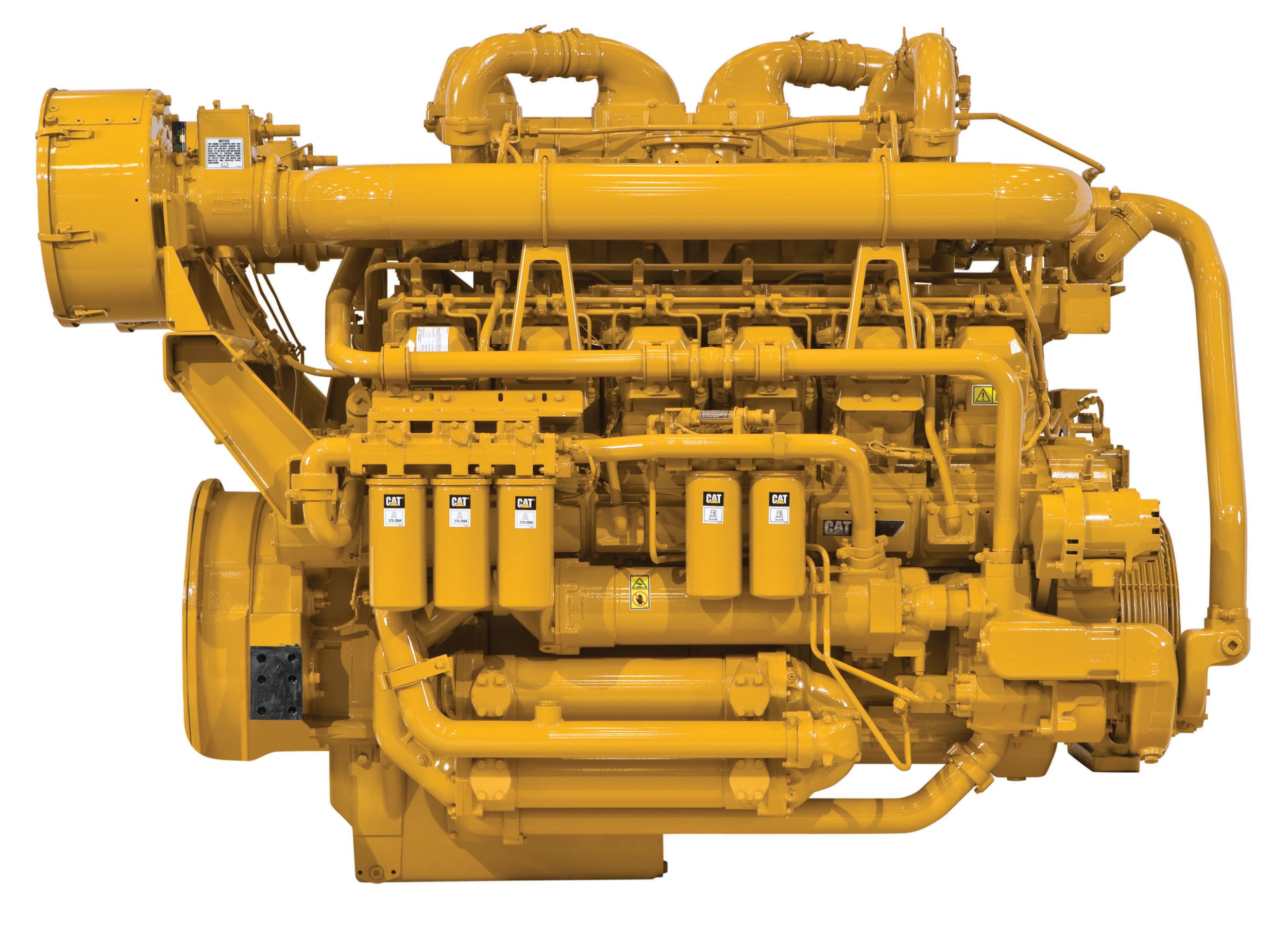

Engine Dimensions - Approximate

Height

68 inLength

105 inWeight - Net Dry - Basic Operating Engine Without Optional Attachments

13400 lbWidth

67 in -

General

Aftertreatment

-Aspiration

Turbocharged AftercooledBore

6.7 inCompression Ratio

13.0:1Displacement

3161 in³Engine Configuration

V-12, 4-Stroke-Cycle DieselRotation from Flywheel End

CounterclockwiseStroke

7.5 in -

Power Rating

Maximum Power

1500 HPMaximum Torque

4580 lb-ft @ 1400 rpmMinimum Power

1020 HPRated Speed

1200-1800 rpm

Air Inlet System

- Aftercooler core, corrosion resistant coated (air side)

- Air cleaner. Regular duty, dry, panel type with service indicators, turbocharger, jacket water aftercooled.

- Turbocharger, rear mounted

- Jacket water aftercooled

Control System

- Governor, RH, 3161 with self contained synthetic oil sump

- Air-fuel ratio control

- Mechanical speed control, without torque control

- Governor control

- Positive locking

Cooling System

- Thermostats and housing

- Jacket water pump, centrifugal

Exhaust System

- Exhaust manifold, dry

Flywheels and Flywheel Housing

- SAE No. 00 flywheel

- 183 flywheel teeth

- SAE No. 00 flywheel housing

Fuel System

- Fuel filter, with service indicators, cartridge type with RH service

- Fuel transfer pump

Instrumentation

- Instrument Panel, RH

- Engine oil pressure gauge

- Fuel pressure gauge

- Oil filter differential gauge

- Jacket water temperature gauge

- Service meter, electric

- Tachometer

Lube System

- Crankcase breather, top mounted

- Oil cooler

- Oil filler

- Oil dipstick

- Oil pump

- Oil filter, cartridge type with RH service

- Shallow oil pan

- Fumes disposal (not installed)

Mounting System

- Rails, mounting, engine length, 254 mm (10 in), industrial-type, C-channel.

Power Take Off

- Accessory drive, upper RH

- Front housing, single sided

Protection System

- Junction box

- Manual shutoff, RH

- Safety shutoff protection, energized to shutdown

- Low oil pressure, low idle 69 kPa (10 psi); high idle 207 kPa (30 psi)

- Water temperature

- Overspeed

- 3161 governor solenoid energized to shutdown

Starting System

- Starting switch

General

- Vibration damper

- Lifting eyes

- Paint: Caterpillar yellow, with optional colors available at request